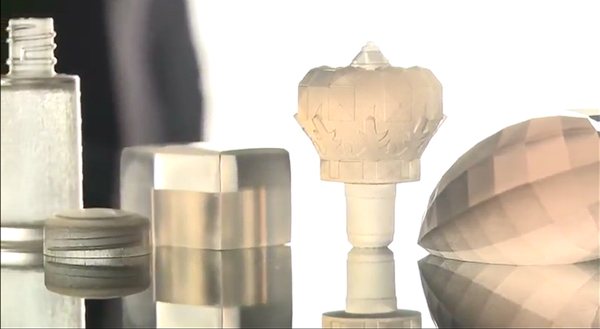

Collcap gives customers the chance to hold a working model of their concept – within days.

As the first major cosmetics packaging supplier to invest in rapid prototyping, Collcap offers a fast, cost-effective service based on experience and expertise.

‘Our 3D printing puts the product in the customer’s hand before any tooling is made. This in turn reduces the pilot stage of the product because if the customer requires any changes we can make the adjustment to the drawing and produce another model in a matter of days, rather than waiting for tooling adjustments and further samples to be produced.’

Adam Smith, Technical Manager

With the technology based in-house, and a dedicated design team, Collcap’s rapid prototyping process takes just days from receipt of the CAD designs.

All Collcap customers now have the opportunity to hold a functioning model in their hands before committing to tooling costs and without the associated timescales, offering the potential to reduce lead times substantially.

Models can be weighted, coloured and sprayed to give customers a true feel for their product before production tooling.