Cosmetics Business rounds up the latest mask base formulations, meeting trends for ingredients and tecniques for creation.

From potent mask bases to special effects – here are four active formulations:

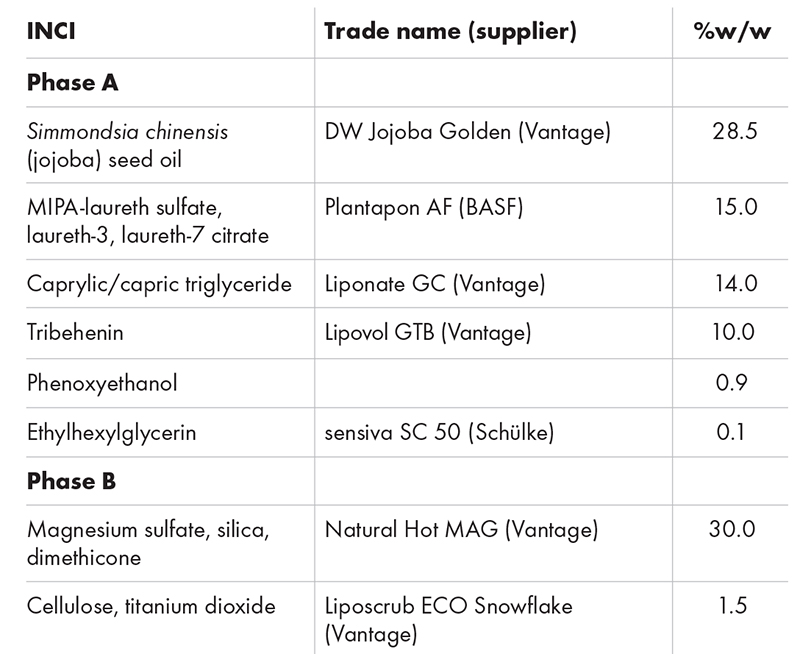

Formulation 1

An exfoliating heat mask with Natural Hot MAG from Vantage, a water-activated self-heating

Preparation

In the main vessel equipped with a medium speed propeller mixer combine phase A ingredients. Heat to 75°C. Mix until uniform. Begin to cool batch. Add phase B ingredients one at a time at 70°C. Mix until uniform. Drop batch at 45°C.

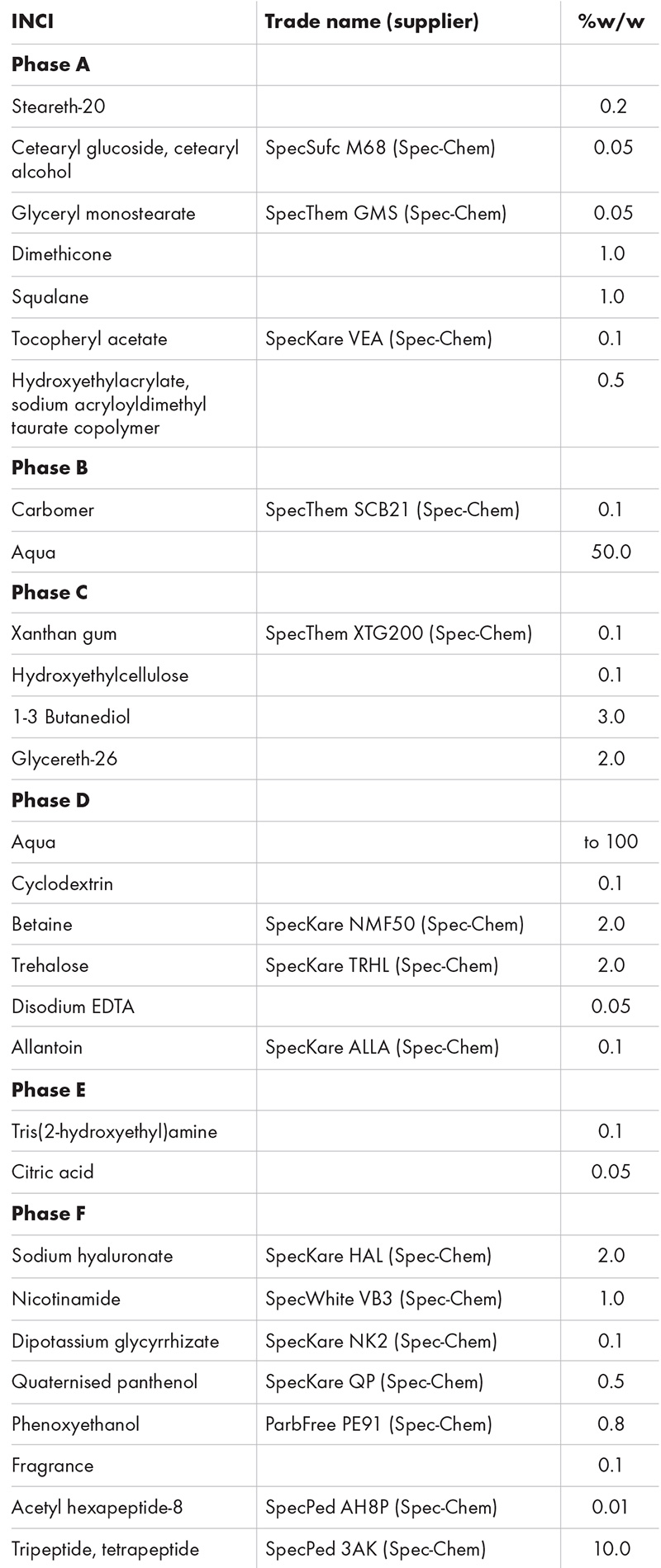

Formulation 2

A milky, youth-boosting mask base from Spec-Chem Industry.

Preparation

Mix B. Heat to 85°C. Prepare D; add to C. Heat to 85°C. Add B and stir. Mix A. Heat to 85°C. Mix A with BCD. Stir for 30 minutes while cooling to 60°C. Add E. Add F at 40°C. Cool to room temperature.

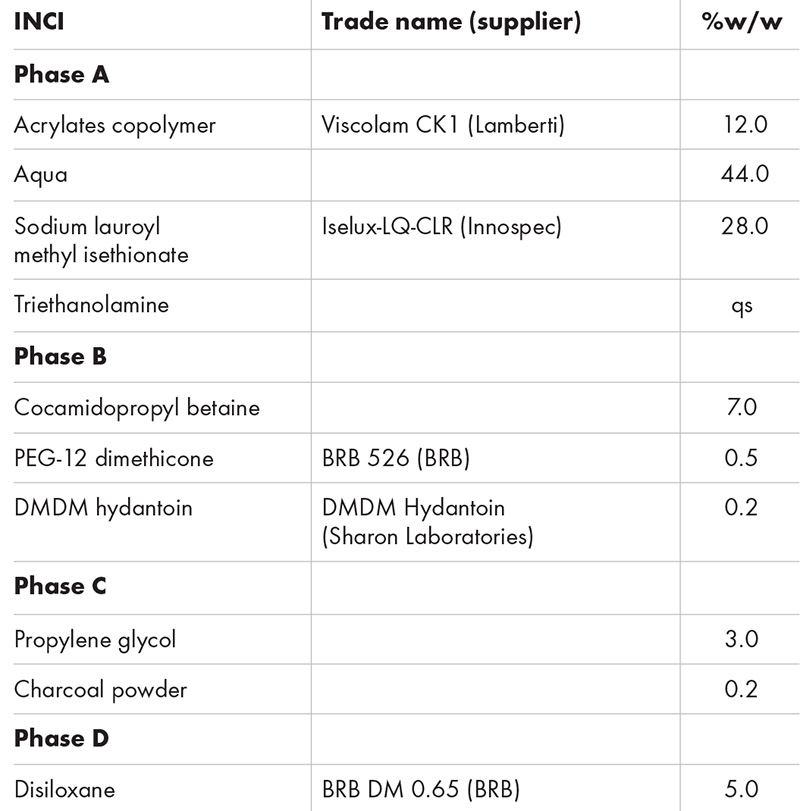

Formulation 3

BRB’s Face Bubbling Black Mask With Charcoal eliminates impurities and traces of pollution. Its gel texture transforms into micro-bubbles upon contact with air, with the bubbling effect provided by BRB DM 0.65.

Preparation

Add acrylates copolymer and water into a beaker and mix well. Add in the sodium lauroyl methyl isethionate. Mix well. Adjust pH to 6-7 with triethanolamine. Add phase B one by one into bulk and mix well after each addition. Premix phase C. Add premix into bulk. Add phase D into bulk. Mix well. Fill the product into an airless bottle.

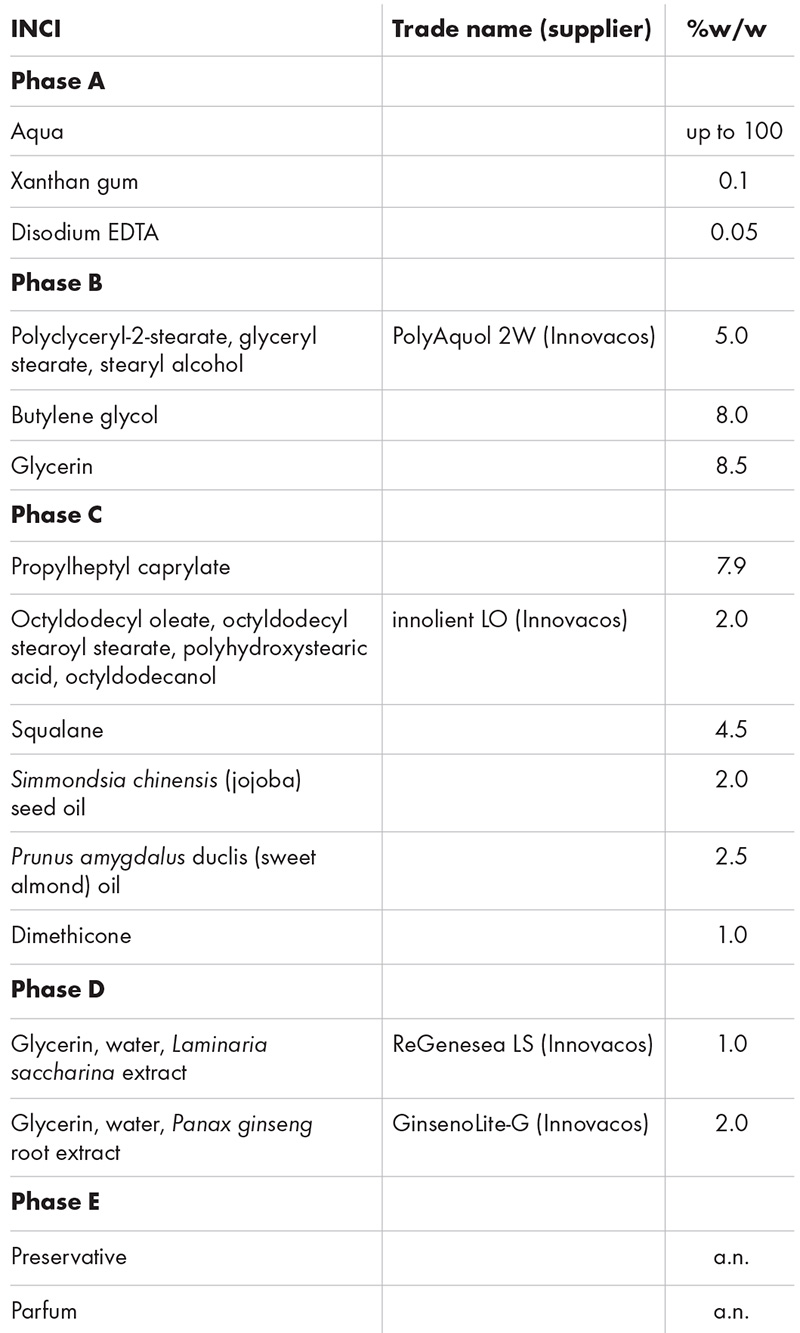

Formulation 4

Because masks aren’t just for the complexion, we’ve included this hand mask formulation from Innovacos containing anti-ageing Laminaria saccharina extract and brightening ginseng root extract.

Preparation

Prepare phase A, B and C separately and warm them up to 75°C. Disperse the thickener in the water phase using a suitable dispersion unit. Add phase C to phase B under stirring. Add phase B and C to phase A and homogenise for a few minutes. Cool down to 40°C and add the ingredients of phase D and E in the given order under gentle stirring.