In this week's The Final Word column, John Morris, Chief Executive of The British Aerosol Manufacturers' Association (BAMA) discusses the ongoing innovation in the aerosol industry.

The technology that dispenses products from aerosols has been around for over 80 years – so how does the aerosol industry stay innovative? The easy answer is to keep the format fresh and modern by innovations in design and packaging. Of course, this is less easy to achieve and results from enormous input of creativity, research, design and technological innovation.

Packaging variety

Aerosols are used by some 2000 brands in over 200 product types and are a safe, hygienic, efficient and sustainable means of dispensing. They are usually made of high grade metals, steel or aluminium, which are recyclable. Innovations over the past decade include: shaped cans, new print technologies, product launches, sustainability improvements and component advances.

The most recent innovation is Unilever’s ‘compressed’ aerosol, which resulted in half-size deodorant cans that last just as long but, the manufacturer claims, has on average a 25% lower carbon footprint per can. The launch of the range has meant 50% less propellant gas and 25% less aluminium per can, 35% reduction in transport emissions and 53% more products on a pallet.

Meanwhile, in 2004, Crown introduced the contoured can to help combat counterfeiting issues and create greater consumer appeal and improved handling. The company also launched new print technologies such as ‘Patterned Varnish’ that created a reflective 3D effect, giving aerosols a distinctive look and feel. Cebal’s (now Ball Aerocan) can-shaping technologies included embossing/debossing that produced unique effects, such as the indentations found on the side panels of Unilever’s Lynx deodorant spray, and USC Europe (now Ardagh) launched a ‘Beading’ process, which gave the visual effect of 3D bangles around the can.

Never-before-seen ingredients

In 2006/7, Beiersdorf UK introduced the Spray Plaster and, with Colep, launched Nivea Visage Oxygen Power which, for the first time, mixed oxygen into a cream. This was achieved by perfecting a bag-on-valve system technology that ensured the oxygen was contained and protected within the aerosol until dispensed.

Being environmentally aware

In 2009 BAMA launched the BAMA Awards, which have highlighted industry innovations, new designs and improved technologies. These awards have underlined the success of the industry as well as the continuous development of aerosol products and the improvement in sustainability within the manufacturing cycle.

In 2012 Ball Corporation announced a metal technology breakthrough that enabled the use of recycled aluminium in the manufacture of extruded aluminium packaging for aerosols. The resulting new metal alloy exhibited increased strength and allowed light-weighting of the container without affecting the pack’s integrity.

All of this innovation has been achieved against a backdrop of safety and standards, and this is where BAMA provides leadership. It is essential for this industry to be continually striving for innovations, not just in design and consumer appeal, but also in environmental sustainability and standards of manufacture and supply.

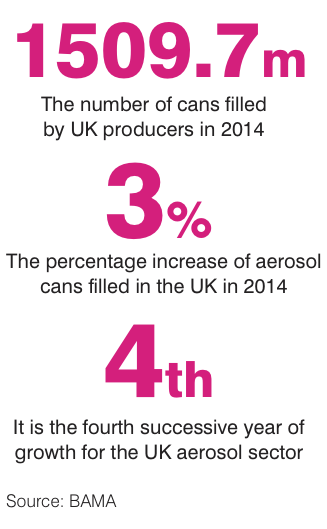

Continued success

Aerosols as a packaging format remain popular among brand owners, retailers and consumers not least because the industry is always looking to improve and innovate and is a prime example of British manufacturing and export success. The industry successfully demonstrates that even though the basic principles of an aerosol remain unchanged, many other advances keep this convenient packaging format as popular as ever. Globally, the UK fills around one in ten of the world’s aerosols, rising to one in five of all aerosols destined for the personal care sector.