Cosmetics company Donna-Klare NZ Ltd has purchased a Silverson Laboratory mixer through Advanced Packaging Systems, Silverson representatives in New Zealand, allowing them total in-house control of quality assurance for their luxury skin care products.

Donna-Klare skin care prides itself on their use of traditional herbal medicine practices and principles in their skincare range. It is a completely different paradigm in skin care.

The company formulate, develop, and trial their products, which are made using the highest quality plant ingredients to make sure that they support skin healing, regeneration and skin health.

One customer had very problematic skin and had tried numerous face creams over the years but had never been able to tolerate anything. Donna-Klare formulated their Longevity No.2 product with all-natural botanical ingredients using their Silverson L5MA mixer and the customer was so thrilled with its performance that she insisted on buying a complete production run!

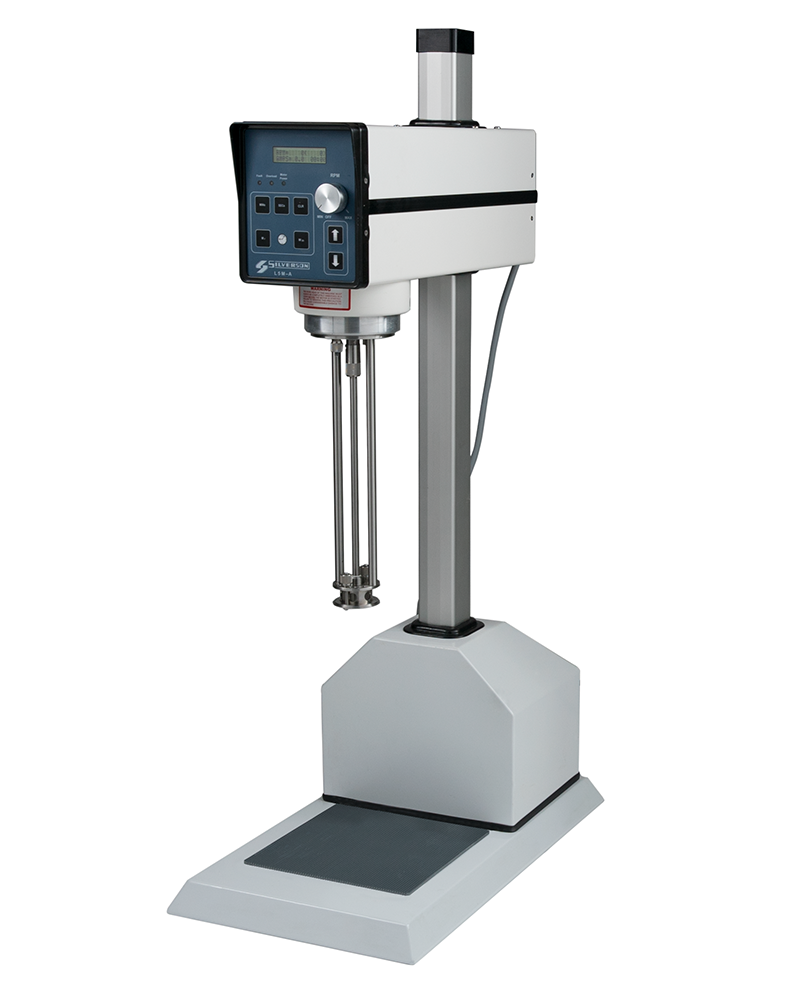

Purchasing the Silverson L5M-A laboratory mixer for their research work, Donna-Klare have been conducting field trials for the past three years to perfect their unique 100% natural skin care formulations for a number of products which are now being used by customers in the UK, Australia and New Zealand.

Donna-Klare choose to use a Silverson mixer for their business due to the design and build quality of the machine, the total in-house control of quality assurance and Silverson’s reputation as the world leader in high shear mixers.

Silverson’s network of representatives meant that Advanced Packaging Systems were on hand nearby to assist Donna-Klare with the selection and purchase, as well as after-sales support which Donna-Klare has said “made working with Silverson a pleasure”.

The versatility of the Laboratory mixer was another benefit of choosing a Silverson mixer. With over 40 interchangeable workheads and mixing assemblies available for the L5M laboratory mixers the machine can be adapted to perform a wide range of mixing operations which may otherwise have needed extra mixing equipment.

Emulsifying, homogenising, disintegrating, dissolving, dispersing, blending, particle size reduction and de-agglomerating can all be done with a single machine, by quickly and simply changing from one workhead to another.

Donna-Klare found that the performance of the Silverson machine with its range of workheads allowed them to experiment with the formulation until they produce their optimum end product - high quality creams with exceptionally fast results and efficient performance with the active botanical extracts penetrating throughout all the layers of the skin in order to support skin healing, rejuvenation and longevity.

Not only has the Silverson mixer helped to improve the end product effectiveness, it has also optimised the production of the creams, virtually eliminating air and heat in the emulsifying process.

For now Donna-Klare are working on a Laboratory scale, but as the business continues to expand and grow they plan to use Silverson’s production scale mixers to keep up with customer demand.

All Silverson mixing equipment is engineered to the same fine tolerances, meaning they can easily scale up without the need for reformulating their products for manufacture on a larger scale.

This makes working together a win-win situation for both companies. And Silverson hope to continue assisting Donna-Klare with the production of their cosmetic products into the future as their business grows.

If you’d like to find out more about Donna Klare, visit their website.

If you’d like to find out more about how Silverson Machines can help with your cosmetic application visit the Silverson website, or contact sales@silverson.co.uk.