Developed to impart a pearlescent or ‘shimmer’ look to products, effect pigments are a cosmetics and toiletries staple. But what are they made from and how exactly do they achieve their visual impact?

Lou Sanders, Technical Development Chemist at Aston Chemicals Ltd, provides some insight

Over to the expert...

Lou Sanders, Aston Chemicals

Effect pigments are used to give a pearlescent, sparkly or shimmery effect to cosmetic products.

They enhance colour cosmetics such as eyeshadows and highlighters by providing a spectrum of effects: from a satin finish to a glittery appearance.

In toiletries they give a shimmery effect to shower gels and shampoos, and in skin care they are often used to provide subtle radiance.

Effect pigments differ from traditional absorption pigments because light is not just reflected from their surface – it is also reflected from surfaces within the structure of the material, giving an unusual and aesthetically pleasing effect, similar to that seen in nature in peacock feathers and fish scales.

In fact, the first versions of effect pigments consisted of guanine and hypoxanthine, extracted from fish scales and crystallised into highly refracting platelets.

Today’s effect pigments are based on a variety of substrates, eg natural mica, synthetic mica (synthetic fluorphlogopite), calcium sodium borosilicate, bronze and aluminium platelets.

Metal effect pigments consist of thin metal platelets, which scatter light and give a metallic ‘hiding’ effect – the vast majority of light is scattered from the substrate, very little penetrates through and the pigment appears almost opaque.

The most commonly used special effect pigments are interference or pearlescent pigments. These are based on a non-metallic platelet substrate, coated with thin layers of refractive titanium dioxide, creating reflective internal boundaries.

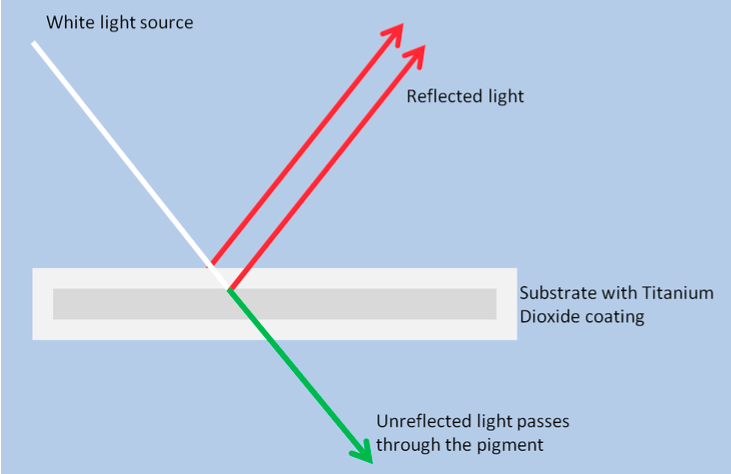

When white light hits the pigment, some light is reflected from the surface, some from the internal boundaries and some penetrates through, giving a transparent and pearlescent effect (figure 1).

Figure 1: Light reflection and penetration in interference pigments

The reflected light waves interfere with each other, either intensifying or diminishing their colour, hence the term ‘interference’ pigments.

The effects can be altered by changing the following parameters:

· Substrate material: The choice of substrate has an effect on the overall appearance. For example, calcium sodium borosilicate has higher transparency and a smoother surface than mica therefore gives a more glossy appearance;

· Platelet size: A smaller size gives a more opaque, silky effect, whereas a larger size gives a more transparent, sparkling effect (figure 2);

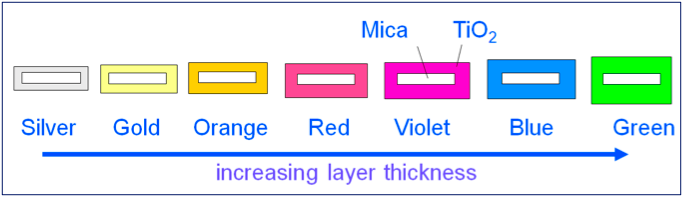

· Titanium dioxide layer thickness: Increasing thickness changes the wavelength of the reflected light and therefore the interference colour changes;

· Surface colours: Substrates can be surface treated with pigments such as iron oxides, ferric ferrocyanide or carmine, which give stronger colours to effect pigments.

Figure 2: Interference colour changes with thickness of titanium dioxide coating on pearlescent pigment substrates

Effect pigments are plastic-free and therefore aren’t classified as microplastics under EU regulations and are the perfect option for clean beauty formulations.

While natural mica may seem to be the obvious choice for a ‘clean’ formulation, there have been ethical concerns regarding some sources of natural mica. Manufacturers have worked to ensure that their natural mica is sourced fairly, but some brands have opted to use synthetic mica-based pigments instead.

Formulating with special effect pigments is relatively straightforward; they are generally stable at high temperatures and in a wide pH range, and are compatible with aqueous, emulsion and anhydrous formulations.

However special effect pigments with coloured surface treatments tend to be less stable in extreme conditions. Metal effect pigments are less heat tolerant and should not be included in water-containing formulations.

Special effect pigments should be added after homogenisation or grinding, as high shear can disrupt the metal oxide layers and reduce the pearlescent effect.

Compatibility can be improved in some cases by using surface treated effect pigments. For example, in cases where there is an incompatibility with an active material, the surface treatment can be used to contain the effect pigments in the opposite phase to reduce contact with incompatible materials.

Special effect pigments have come a long way since the days of fish scales, and offer a wide range of beautiful effects, from a subtle shimmer to a vibrant metallic sparkle – there really is a special effect pigment for every formulation!